I. STEEL vs. NICKEL

Alloy is what makes the sound of your strings. But how do you choose it?

The specific grain of your SKULL STRINGS has always been its stainless steel. Completely nickel-free (allergy sufferers will appreciate this), and with the lowest level of impurities on the market, your steel SKULLS have a brilliant, slamming sound, with very high harmonics and high trebles combined with massive bass ! A sharp sound, perfect for shredding, so dear to our extreme music.

Your SKULLS are not coated. Unlike other brands, SKULL STRINGS focuses on the intrinsic qualities of its raw materials. To be considered stainless, steel must contain a minimum of 11% chromium. And the stainless steel in your SKULLS contains 17%. This chromium reacts with moisture in the air to form a passive layer of chromium oxide on the surface of your strings. It is this transparent layer that protects your strings from deterioration. Simply remove this passive layer with a dry cloth before playing, and your strings will sound like new for longer. SKULL STRINGS last longer!

NB: Do not use greasy cleaning products on your steel SKULLS. The greasy component of these products encrust the chromium oxide layer in the thread turns, choking your strings. A simple micro-fiber is all you need to clean your strings. There are no contraindications for nickel SKULLS.

So that every musician can find THE sound that’s right for him, while benefiting from SKULL STRINGS quality and expertise, we also offer a NICKEL line ! With its warmer sound, enhanced mids and soft touch, it’s ideal for slide!

(Note that, in comparison, stainless steel has a rougher feel. But musicians who prefer the sound of stainless steel soon get used to it).

SKULL STRINGS does not differentiate on price, so that each musician can choose according to sound, not price.

So, what’s your favorite ?

II. HOW IS A STRING MADE?

Well, no !!!!! You don’t press a button and hop ! You get a string !

A string consists of a round or hexagonal core, onto which a wrap wire of the chosen alloy (steel, nickel, phosphor-bronze, soft brass, silver-plated copper) is wound. This core is tensioned before the wrap wire is unwound onto it. At SKULL STRINGS, we have chosen to spin at a slow speed, so as not to overheat the material, which would cool unevenly and not give the string the precision of a perfect string. After spinning, your strings are checked with a micrometer and a finger to ensure the most even thread possible. And for heavy gauges, each string is mounted on a monochord to ensure the be

st possible fit.

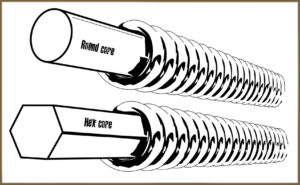

III. CORE & WRAP WIRE

There are two types of core for guitar and bass strings. The long-used round core and the hexagonal core. While the round core is integral with the wrap wire, the latter rests on the 6 edges of the hexagonal core for better cohesion and a distinctive sound. By comparison, a recurring problem with round cores is the slippage (accordioning) of the wrap wire over time. That’s why SKULL STRINGS only offers carefully spun strings on hexagonal cores…

… and why not something new very soon ? Stay tuned !

As for the wrap wire, it’s round at SKULL STRINGS! Although more textured than a flat thread, the round one has a more massive sound and a strong presence, especially in the high frequencies, for greater impact and sustain! It provides good attack and better definition. With its stainless steel, it’s all the grain of your SKULL STRINGS.

IV. HEAVY CORE

What’s HEAVY CORE?

It’s a core-to-wrap ratio that favors a more massive core than in a “traditional” ratio, for the same gauge.

As a result, Heavy Core strings offer greater tuning stability and an ideal response for more aggressive playing styles.

All your SKULL STRINGS are Heavy Core from the .052w.

And, on request, we can modify the core/wrap ratio to give you the best playing comfort : yours.

V. ACOUSTIC & CLASSICAL SKULLS

Unlike our electric strings, acoustic & classical SKULLS are coated. This is the case with Phosphorus-bronze, Soft Brass and Silver-plated alloys.

But then again, SKULL STRINGS doesn’t do what everyone else does! While your strings are protected by an anti-sulfuration varnish that gives them incredible longevity, SKULL STRINGS innovates by coating not the string, but the wrap wire itself. This means optimum protection without a complete coating (which would alter the sound) between your string and your pickup.

photo by- MIND (@monsieurmind) | Profil Instagram

photo by- MIND (@monsieurmind) | Profil Instagram

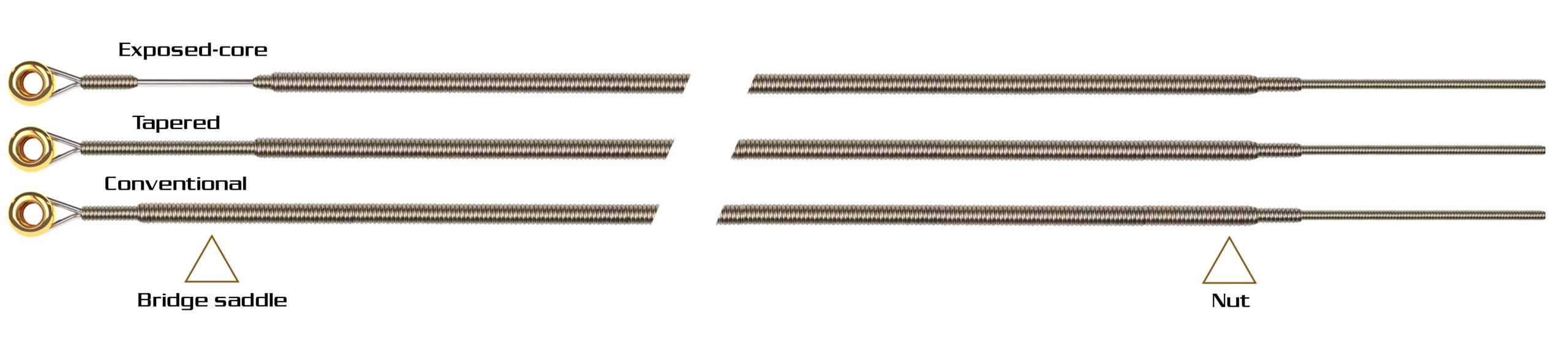

VI. EXPOSED CORE & TAPERED WOUND

For heavy gauges (and others on request) SKULL STRINGS offers EXPOSED CORE & TAPERED WOUND!

Inspired by piano strings, EXPOSED CORE leaves the first few centimeters of the core bare. With less material resting on the saddle, the string’s sustain and intonation are greatly improved. All you have to do is pull up the saddle to regain the original pitch. By the way, a trip to your favorite luthier or guitar tech is not a bad idea, especially for a first Exposed core session 😉

From B .125/.135 to .175, SKULL STRINGS offers you its now famous EXPOSED CORE winding.

Another solution is TAPERED WOUND, the intermediary to traditional winding.

And of course, all our strings, even the heaviest gauges, are available in traditional winding !

VII. CUSTOM TO THE BONE!

SKULL STRINGS is the unconditional specialist in custom sets. From .008, .009, .0095 (…) to .175 bass, we’re here to find solutions for the best playing comfort for every musician.

Do you already know the gauges you need, but it doesn’t yet exist in the SKULL STRINGS references? Go to our BUILD YOUR OWN module, where you can choose your tuning, scale (multiscale or standard), alloy and string tension.

In doubt or need more information ? Our advice service is here to help. Go to the comments section and tell us about your tuning and the specificities of the instrument, and we’ll work out solutions with you.

PS : To create the best set for you and your needs, and to respect the integrity of the instrument, we may need to ask you :

* the distance from the ball to the saddle

* the distance from the bridge to the top nut (scale length)

* the distance from the top nut to the tuning pegs.

Because this is the work of a tailor ! We tailor your set exactly to your needs and the specificities of your instrument. SKULL STRINGS, CUSTOM TO THE BONE !